Winterhalter Converyor Dishwasher

Restaurants, hotels, refectories and canteens. Those working here know: Sometimes, it has to go really fast. Also in the kitchen. Stacks of plates, cups, glasses and cutlery must be hygienically cleaned in no time at all. This is precisely why Winterhalter has developed the C50 rack conveyor dishwasher: The warewashing system was developed for maximum performance and is designed for maximum speeds. With compact dimensions and modules that can be combined individually. For first-class wash results while requiring little space

RAPID WASHING SPEED. The major strength of the C50 is in its capacity: It can reach up to 260 racks per hour. And all this with compact dimensions and low space requirements. Three different speed levels allow you to adjust the wash cycle to suit the volume of wash items. With this, you are ready for anything. Even at peak times.

MAXIMUM FLEXIBILITY. The C50 gives you full flexibility: The machine is available in two basic versions single rinse and dual rinse. The modular system also offers different configuration and installation options. Pre-cleaning zone or drying zone? Possibility for HighTemp mode? Mechanical or electrical corner conveyor? Linear or corner inlet table? It is all possible – and can of course be upgraded later.

HYGIENE SAFETY. The C50 is specifically designed for first-class wash results, hygienic cleanliness and excellent drying: With a standard tank heating performance of 18 kW, upgradeable to a whopping 27 kW (HighTemp), and a thoroughly considered hygiene design. The boiler heating always operates with a stable 27 kW independent of the water pressure provided on site: This guarantees consistent and perfect rinse results.

USER-FRIENDLY. The C50 is simple: Simple to install, simple to operate and simple to clean. The display is self-explanatory and language-neutral. Automatic programmes help you during the cleaning and ensure fast emptying and filling of the machine. Thus, your C50 is ready for use in no time at all.

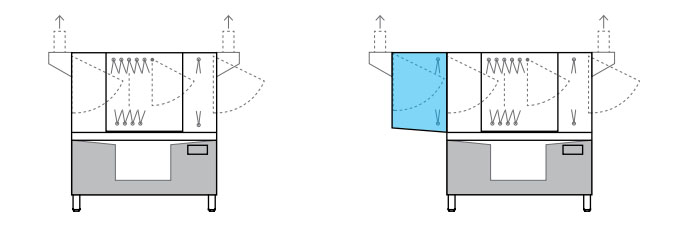

MACHINE VERSIONS

Available in the single rinse version with compact external dimensions and optimised intervals between the internal washing process. Also available for dual rinse version with an additional pump rinse for the optimum removal of particles.

BACK PANEL OF THE MACHINE

For working conveniently and an energy-efficient operation: Standard machine rear cover to reduce noise and heat emissions. A smooth inner surface for easy and fast cleaning.

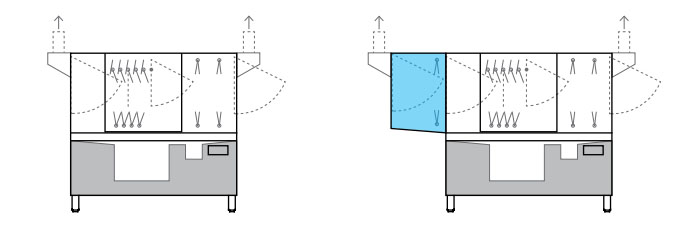

PRE-CLEANING ZONE

Is available as an optional module, which extends the main wash zone and increases the rack capacity of the machine: Separated by a long curtain, large pieces of food are removed with the aid of additional wash arms. Can also be retrofitted.

HYGIENE CONCEPT

Washing quality and hygiene of the highest standard: Hygiene design with double-skinned hygiene doors and deep-drawn tank base. Double filtration system with a pump inlet filter and a full coverage flat strainer. Non-pressurised boiler, powerful tank heating and optional HighTemp kit.

Custom configuration options. The C50 can be tailored exactly to your requirements and your situation on site. In addition to the pre-cleaning and drying zones, as well as the HighTemp option, exhaust air adapters and other accessories are also available: Inlet and outlet tables made of stainless steel; the inlet can also go around the corner. Stacking, sorting and clearing stations.

Mechanical and electrical corner conveyors at 90- and 180-degree angles. This means: You are free to plan and have a wide range of installation options. For an individually-tailored and efficient washing process

WASHING PERFORMANCE

Fast and efficient: Up to 260 racks per hour. High performance with compact dimensions and low space requirements. Three individually adjustable speeds according to customer requirements: Intensive, Standard, Fast. Automatic rack-controlled activation of the individual wash zones for cost-effective operation

HIGHTEMP

For special requirement, all variants are available in HighTemp version – washing at high temperature and meeting thermolabel compliance.

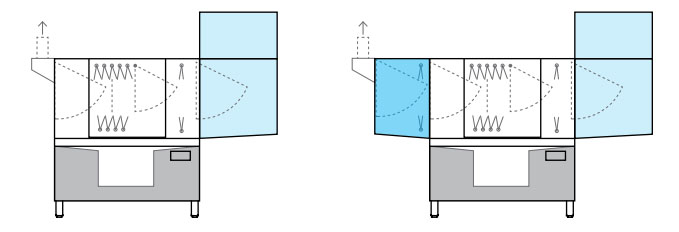

DRYING ZONE

Available as an optional module and can be retrofitted later. This allows the wash items to be used again straight away.

OPERATION

Self-explanatory, language-neutral and colour-coded display for easy operation. With automatic programmes for cleaning support, quick emptying and quick filling. This allows the C50 to be ready for operation in around 15 minutes. Including drain pump and an automatic programme for emptying the machine as standard: without contact with the wash water. For more comfort and work safety.

MACHINE CONCEPT AND VARIANTS

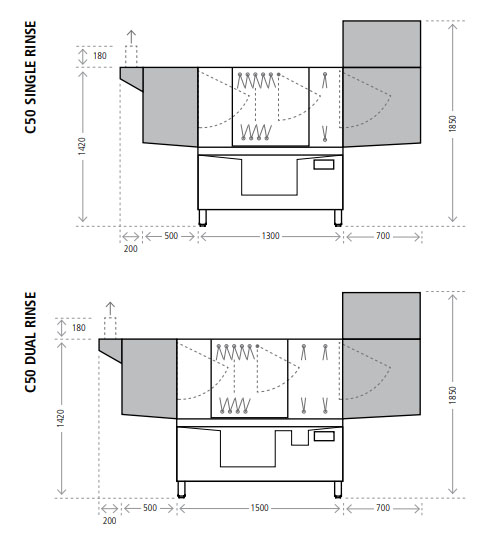

C50 SINGLE RINSE

BASIC MACHINE.

With single rinse and compact dimensions. In linear configuration or as corner installation. Ideal for small and angled spaces.

Theoretical capacity Racks / hr*1 (Standard) : 70 / 110 / 165

(HighSpeed) : 70 / 130 / 200

Dimension W x D x H (mm) : 1300 x 800 x 1420

Rinse water consumption l / hr*2 (Standard) : 230

(HighSpeed) : 260

WITH PRE-CLEANING ZONE.

Increased machine capacity offers higher volume of wash items.

Theoretical capacity Racks / hr*1 (Standard) : 90 / 140 / 210

(HighSpeed) : 90 / 170 / 260

Dimension W x D x H (mm) : 1800 x 800 x 1420

Rinse water consumption l / hr*2 (Standard) : 260

(HighSpeed) : 300

C50 DUAL RINSE

BASIC MACHINE.

With pump rinse that improves rinse result and provides a slight increase in machine capacity.

Theoretical capacity Racks / hr*1 (Standard) : 80 / 120 / 180

(HighSpeed) : 80 / 140 / 210

Dimension W x D x H (mm) : 1500 x 800 x 1420

Rinse water consumption l / hr*2 (Standard) : 230

(HighSpeed) : 260

WITH PRE-CLEANING ZONE.

Increased machine capacity offers higher volume of wash items. Pump rinse included for an improved rinse result.

Theoretical capacity Racks / hr*1 (Standard) : 100 / 150 / 225

(HighSpeed) : 100 / 180 / 260

Dimension W x D x H (mm) : 2000 x 800 x 1420

Rinse water consumption l / hr*2 (Standard) : 260

(HighSpeed) : 300

WITH DRYING ZONE.

This allows the wash items to be used again straight away.

Theoretical capacity Racks / hr*1 (Standard) : 70 / 110 / 165

(HighSpeed) : 70 / 130 / 200

Dimension W x D x H (mm) : 2000 x 800 x 1850

Rinse water consumption l / hr*2 (Standard) : 230

(HighSpeed) : 260

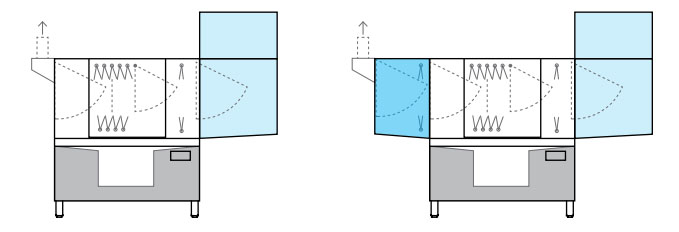

WITH PRE-CLEANING AND DRYING ZONE.

When the cleaned wash items have to be immediately reusable even at peak times.

Theoretical capacity Racks / hr*1 (Standard) : 90 / 140 / 210

(HighSpeed) : 90 / 170 / 260

Dimension W x D x H (mm) : 2500 x 800 x 1850

Rinse water consumption l / hr*2 (Standard) : 260

(HighSpeed) : 300

WITH DRYING ZONE.

This allows the wash items to be used again straight away. Including pump rinse for an improved rinse result.

Theoretical capacity Racks / hr*1 (Standard) : 80 / 120 / 180

(HighSpeed) : 80 / 140 / 210

Dimension W x D x H (mm) : 2200 x 800 x 1850

Rinse water consumption l / hr*2 (Standard) : 230

(HighSpeed) : 260

WITH PRE-CLEANING AND DRYING ZONE.

When the cleaned wash items have to be immediately reusable even at peak times. Including pump rinse for an improved rinse result.

Theoretical capacity Racks / hr*1 (Standard) : 100 / 150 / 225

(HighSpeed) : 100 / 180 / 260

Dimension W x D x H (mm) : 2700 x 800 x 1850

Rinse water consumption l / hr*2 (Standard) : 260

(HighSpeed) : 300

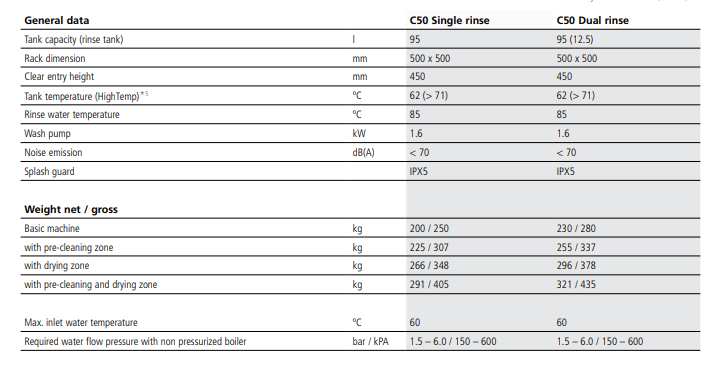

TECHNICAL DATA

EX WORKS OPTIONS

EX WORKS OPTIONS

– Operation direction of travel:

left-right / right-left

– Dual rinse

RETROFITABLE OPTIONS

– Exhaust air adapter (inlet / outlet)*3

– Working height 950 mm*4

– Pre-cleaning zone

– Drying zone

– HighTemp

– Emergency stop switch

– Table limit switch

– 90° corner entry table

– Mechanical corner conveyor 90° (inlet / outlet)

– Mechanical corner conveyor 180° (outlet)

– Electrical corner conveyor 90° / 180° (outlet

INDIVIDUAL PLANNING – A PERFECT FIT IN ANY ROOM

C50 SINGLE RINSE

rack conveyor dishwasher

Hotels, restaurants, canteen meals for 200 – 400 diners

Performance : Up to 165 / 200 Racks / hr

Total length / depth : 3,700 mm / 815 mm

Loading area : Inlet table with sink and pre-spray unit, space for two racks

Unloading area : Outlet roller table, space for two racks

C50 SINGLE RINSE

rack conveyor dishwasher with drying zone

Hotels, restaurants, canteen meals for 200 – 400 diners

Performance : Up to 165 / 200 Racks / hr

Total length / depth : 4,000 mm / 1,550 mm

Loading area : Inlet table with sink and pre-spray unit, space for two racks

Unloading area : Electrical 180° outlet corner conveyor, pivoting roller table, space for two racks

C50 SINGLE RINSE

rack conveyor dishwasher with drying zone

Hotels, restaurants, canteen meals for 200 – 400 diners

Performance : Up to 165 / 200 Racks / hr

Total length / depth : 3,700 mm / 2,100 mm

Loading area : Inlet table with sink and pre-spray unit, space for two racks, mechanical 90° inlet corner conveyor

Unloading area : Mechanical 90° outlet corner conveyor, roller table, space for two racks

C50 DUAL RINSE

rack conveyor dishwasher with pre-cleaning zone

Hotels, restaurants, canteen meals for 300 – 500 diners

Performance : Up to 225 / 260 Racks / hr

Total length / depth : 3,550 mm / 3,150 mm

Loading area : Sorting station, inlet table with sink and pre-spray unit, space for two racks, 90° corner entry

Unloading area : Mechanical 90° outlet corner conveyor, roller table, space for two racks

»We are family people«

Down-to-earth. Forward-looking. With a focus on family. The culture and values of our family have shaped the Winterhalter company for three generations. Close to staff, customers and partners. Long-term thinking with a view to the generations to come. Taking personal responsibility – all typically Winterhalter. We are proud of our family company. And we are pleased to grow a little more every day.

THE FIRST WINTERHALTER

THE FIRST WINTERHALTER

It all began in 1947: Karl Winterhalter established his own company in Friedrichshafen. He started by salvaging scrap metal from the war, which he used to manufacture household goods. Cooking pots and ovens, for example. A short time later he specialised, and in 1957 launched the GS 60 model: the first commercial warewasher from Winterhalter. That was the starting signal. Since then the company has always pursued a single goal: perfect wash results as part of an efficient washing process. With this holistic approach, Winterhalter has developed from a machine supplier to the full system provider of warewashing solutions it is today.

»Products, advice, service – three factors that intertwine seamlessly at Winterhalter. And that makes our customers feel safe in the knowledge that they have the right partner for any issue relating to the washing process.

FROM WAREWASHER TO WAREWASHING SOLUTION

In days gone by, all we needed to do was deliver the new warewasher to our customer’s kitchen on a hand truck. Now it’s about the development of a new, individual warewashing solution, which is perfectly coordinated with the on-site situation and the special requirements and preferences of the customer. A solution of this type is based on clear analysis and planning. To achieve this, we visualise the room layout using state-of-the-art CAD software in 2D and 3D. For a bespoke and efficient washing process.

1,900EMPLOYEES WORLDWIDE

1,900EMPLOYEES WORLDWIDE

High quality standards. Diligence. Curiosity and ambition. These are the typical attributes of a Winterhalter employee. And with them, we have grown from a small Swabian family company into a global player: with over 40 branches worldwide and distribution partners in over 70 countries. We are proud of what we have achieved. And we are proud of each and every employee who has done their bit. So we would just like to take this opportunity to officially say »Thank you!«

IN-HOUSE LABORATORY FOR IMPROVED CHEMICALS

As a specialist in warewashing, do we want to rely on the products of other manufacturers? The answer to this question was an immediate and resounding »No!«. This was the moment when our

in-house research laboratory was born: we have been developing our own formulas for original Winterhalter chemicals for many years now: from detergents and rinse aids to hygiene products.

OUR ACADEMY OF WASHING SCIENCE

Almost 1,000 participants per year and 250 training days worldwide: as part of our training programmes we pass on our knowledge and experience in the discipline of »warewashing«. We provide training to our own personnel as well as to our retail and service partners. Our objective: every Winterhalter customer should receive informed advice and professional support in the specific situation. Whether it’s an initial informative discussion, installing a warewasher, or service and maintenance appointments.

An Asian Success Story

On 27 June 2015, the time had come: The factory Winterhalter Asia Co. Ltd. was officially opened in Rayong (Thailand). After Meckenbeuren and Endingen in Germany and Rüthi in Switzerland, this is Winterhalter’s fourth production facility.

»We are at a point where it is no longer enough to be a German company with a large export share. Our markets are at a different stage of development and have different needs. As an international company the German market is one of many we serve.«, says Ralph Winterhalter. Warewashers are produced in Rayong that are designed specifically for the Asian market. The advantage: They are perfectly matched to the requirements and wishes of Asian customers. And this is precisely why it is so successful.

GERMAN TECHNOLOGY

Quality and excellence don’t just happen overnight. It is a continuous commitment that takes a lifetime of dedication and a passion for your craft that surpasses the norm which is what Winterhalter’s fine range of warewashing products like the C50 are all about. Each and every product from Winterhalter is manufactured to world class standards at our local production plant in Southeast Asia that strictly adheres to the highest German engineering excellence and quality.